Its Alive! We are running two fridges, a portable freezer, 5 Macs, a 12 volt water-maker and the washing machine.

- At the same time.

- On Solar and Lithium, anchored out.

- The inverter is now on 24×7, no moving parts, and no diesel is burned.

- As far as I know, Ad Astra has the largest, greenest electrical power system for a catamaran in her class.

It’s Alive

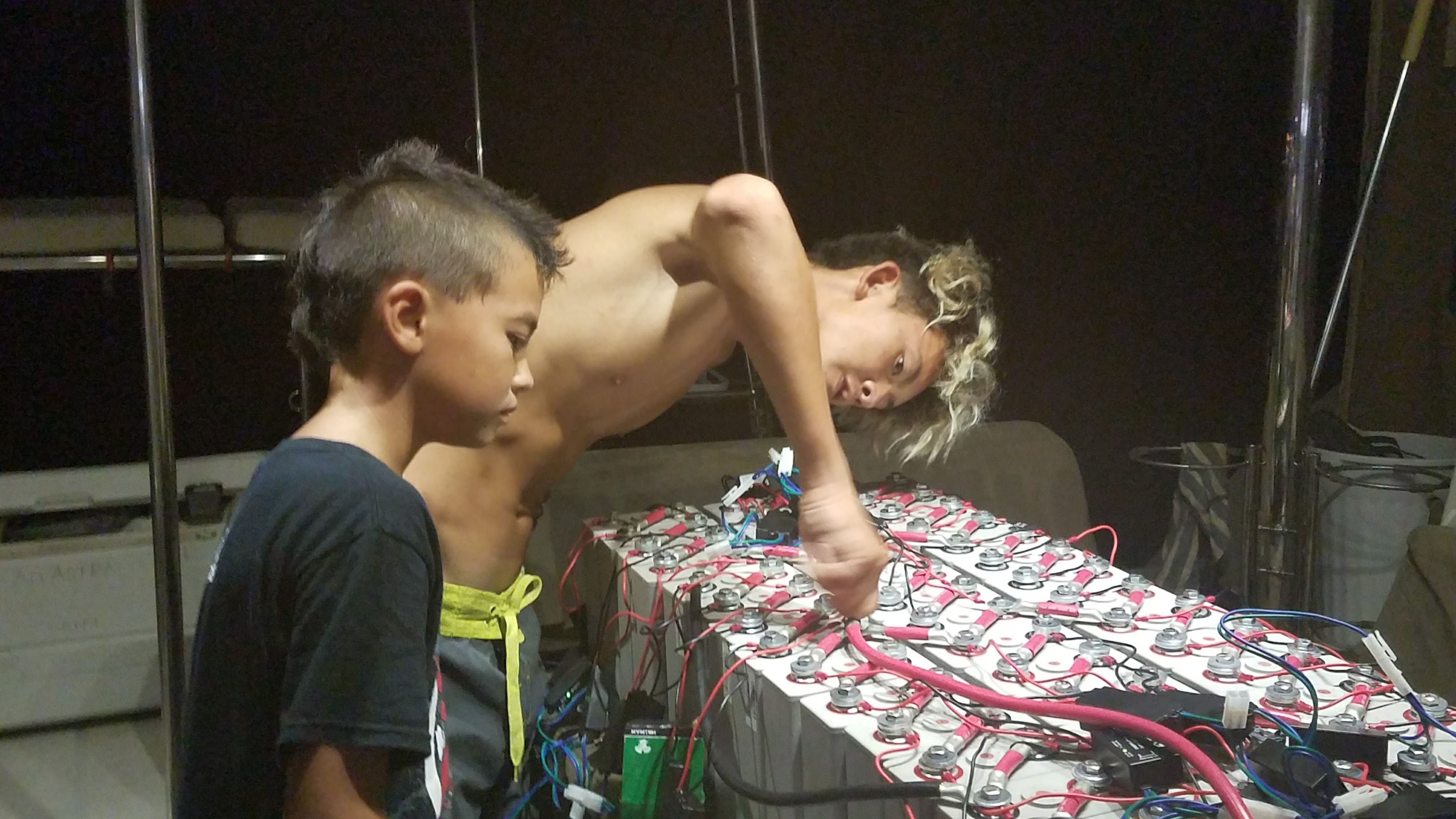

Max and Kyle wiring up the full 4s12p system

Longer discussion of the systems for Ad Astra

After a considerable investment of time and money we now have what I think is the perfect electrical power setup for Ad Astra. We do not need to burn diesel, we do not have the sound and maintenance requirements of wind turbines, with no moving parts it is a solid state world-traveling power plant that happens to be our house, which also happens to be a sailing catamaran.

Factory Installed Systems

Back in 2012, the factory options I chose to power Ad Astra was (2) Yanmar 55HP Diesel engines each with an 80 Amp Hitachi alternator as well as a 5kW Onan Genset. 1100 Amp-hours of Lifeline AGMs for the house bank, but no solar, wind, or hydro generation.

A side discussion of Air Conditioning:

There was an option for air conditioning for about $25-35k (which requires the 11kW Genset), and my dealer talked me out of it. Sometimes in the hot & humid Caribbean summers or at dusk when the mosquitoes attack from their mangroves, I wish we had AC. But even counting those hot days and buggy nights, I think there has been at most 20 days that I really wished I had AC. So at $1k per day for those days, at $500 a night it would be far cheaper to check into the Four Seasons! Instead, we take a swim, find some shade & breeze. Or go into town and find some ice cream. It really is not that hard to stay cool.

Right now I am typing away in the shade with the trade-winds blowing and it could not be more comfortable. In fact, I am getting a bit chilly, might have to break out the rare sweatshirt tonight.

Water-maker

What? Why do you need a water-maker? Sure, 99% of boats stay in a marina and they can just turn on the dock hose. But being full-time cruisers, we are anchored out 350 days of the year. With five people, cooking, showers, laundry, diving, cleaning, we end up using an embarrassing amount of water. About 50 gallons a day, or 10 gallons per person per day. Most of this is actually for the washing machine.

When we started to cruise full-time in 2016 I knew it would get old really fast running the Genset 2-3 hours a day. In fact, the vast majority of cruisers run their engines or generator at least an 1-2 a day. Only the small, single-handed monohulls with truly modest and salty systems get by with 50-200 watts of solar to stay topped up. Most boats with water-makers have the engine powered types that produce an amazing 60-100 gallons of water per hour, but you have to run the engines. We wanted to be able to make water on 12 volts, and ideally from solar.

The best choice for us was the Spectra Newport 400 that produces about 16 gallons per hour while drawing about 9 amps per hour. So we need to run the Spectra for about 4 hours a day. This was our first addition to Ad Astra for full-time cruising.

(We still have yet to rig up our canvas systems for effective water catching – a 2018 project for sure.)

Watts vs Amp-hours?

For those of you who live a 110v or 220v land-life, you never think in terms of Amp-hours. Well, okay, yes you drone enthusiasts do think of Ah. Perhaps you select your appliances and pay attention to the wattage label at purchase time, but for the most part, people on land simply buy an appliance and stick it into the wall. At the end of the month you get a bill for all of your energy consumption – there is no itemized bill for this light, that computer, the TV, the blender, or the decorative fountain. At best, people can see the AC loads in the summer months, but they do not know what is really driving the power bill. For cruising folks living full-time on their boats they actually do know the energy consumption rates of everything on their boat. And while enjoying a sundowner, cruisers eagerly discuss and learn about each other’s Amp-hour consumption of the other boat’s systems.

I would guess that the full-time RV & van “land cruisers” are also extremely knowledgable of their energy systems.

On land, it is possible to buy a “green-switch” or “watt-killer” which is inserted between your appliance and the wall and it will report on the exact wattage consumption of a particular device. It is a great exercise to build a spreadsheet of everything in your house and understand your consumption of watts.

So, why do folks who float talk in terms of Amp-hours and those on land get bills for kilo-watt-hours?

It is part tradition, but it is mostly a math convenience, remember from your physics class that:

P = V*I

Power = Volts x Current

Power (watts) = Volts (v) x Current (amps)

Most boats are based on a 12v system, just like a car and an RV. Bigger boats might go for 24volts or even 48 volts, but the majority are 12v.

So if Volts, v is always going to be 12v, it is simpler to not talk about watt-hours, but instead just Amp-hours.

Let me give some examples to make it more clear.

House Bank

Lets start with the house bank. Every boat, truck, RV, van, car (and plane) has a house bank. For cars it is usually just that lead-acid starter battery. But for the other vehicles there is usually a separate house bank that is electrically separated from the starter battery which is used only to electrically crank the engine until the engine fires, and the alternator then runs and re-chargers the starter battery. The house bank is separated mostly for safety as all of the lights, appliances, and such are basically luxuries apart from the existential need to fire up your engine. (Yes, most systems have a cross-over switch so that you could start your engine from the house bank in an emergency.)

The old Lifeline AGMs we replaced

Our house bank originally was a (12v) 1100 Amp-hour AGM sealed lead battery array of 5 separate monster batteries each over 100 pounds. So, using P=VI the power of this system of batters was 13200 watts or 13.2kW. Sounds like a lot huh? It should be, at 800 pounds and $3000 this was a serious amount of lead. Now these are the best lead-acid batteries you can buy. Sealed, maintenance-free and should be good for about 500 cycles. What is a cycle? Every time you drain your battery and charge it back up again is a cycle. So with that big lead-acid bank we can use 13.2 kW of power then charge it right? Nope. With lead-acid batteries you cannot drain them below 50% often without causing permanent “sulfation” damage (basically the lead layers on the inside fall apart into crumbs). Also lead-acid batteries are extremely difficult to charge to 100% as it has an asymptotic charging curve where it takes more and more energy to charge closer and closer to 100%. Most lead-acid battery banks are “charged” when they are at 85-90% and people call it good enough. Over time, the battery experiences wear and tear on that lead and will lose its storage capacity. For new batteries that are charged to 90% and down to 50% you have 40% of your total power available, but a more practical rule of thumb is 30%. So, for our big old AGM lead bank we had 30% of 13,200 watts or about 4000 watts of power that we could effectively use before needing to charge them again. Speaking in boater terms of amps that is about 333 amp-hours of effective storage.

How much energy do we need each day?

With lights, computers, water pumps, 2 fridges & 1 freezer we run at about 27 amps per hour (or 27 x 12 = 325 watts per hour. 27 amps x 12 hours = 333 amp-hours. So 333 amp-hours divided by 27 is about 12 hours between charge cycles. Before our solar installation we did run our generator in the morning and in the evening like most cruisers. To get back from 50% charge to 90% charge we need to put back those same 333 amp-hours – each 12 hours of everything being on. On a more normal day we use between 300-400 amp-hours. and so with the twin Yanmar diesels with the 80 amp Hitachi alternators we could charge our battery bank in two hours: 2 x80 = 160 amps x 2 hours = 320 amp-hours. Or more fuel efficient, we would actually use our Onan 5kW Genset, but that math is more clear with the Hitachi for this purpose.

Do you see yet? If you work exclusively in 12v, then all of your numbers are smaller by a factor of 12.

Two hours in the morning, two hours in the evening. Two diesel engines running at about 2000 RPMs and using about 0.75 gallons per hour each, so 0.75 gallons x 2 engines x 2 hours x $4 per gallon for diesel = $12 to “fill-up” our batteries for each cycle, or $24 a day! This works out to be about $8800 a year for just the fuel. But that is not all, at 4 hours a day the generator will see about 1500 hours of use. With oil changes at least every 150 hours (10x), new impellers at 500 hours (3x), new v-belts every 500-1000 hours(3x), and other maintenance you are easily looking at another $1k of maintenance. So, in round numbers: $10k a year / $800 a month for electricity.

Many of my cruising friends would be (vigorously) pointing out that we are energy hogs. Folks have cruised for decades with 5% of that electrical consumption, and even less. That is true. I will own that. But for our family of five, we come from a background of online game development. We write software during the day, and play games in the evening and watch movies at night. We live in a four bedroom, four bath house, that happens to sail. This is what we are about and want. We basically want to plug are macs and anything else into the “wall” like on land – whenever we want – AND we do not want a bill – nor do we want to run a diesel engine for hours of the day. Right? Why not have your cake and eat it too?

Why Solar wins

Okay so first thing is we need to generate power from non-diesel sources, wind or solar?

Globally according to wikipedia, we have 303 GW of solar production and 487 GW of wind production and wind is kicking ass in Northern Europe to Texas. And sailboats are the classic wind machine, so wind wins right? Well, let’s check it out:

Wind Power = k Cp ½ ρ, A V3

Where k, Cp, ½ and ρ are constants

So the only two variables you can play with are A and V

A is the circular area of your windmill and V is the velocity of the wind.

Bigger windmills make more power of course, but there is a simple space constraint on how big of a windmill you can install on your bout. Typically it is limited to about 1.5m or 4 feet in diameter. You must mount them where they will get a clear stream of wind and very much away from any fleshy bits of the crew. So A is practically fixed, then you are left playing with V the velocity of the wind. The neat thing about V is the power is proportional to the cube of the velocity!

Sailors like big V/wind right? Well. We actually like it between 15 and 25 knots. More than that and it can be distracting, we can certainly sail in 25-35 knots safely and even comfortably, but we must be extra vigilant. 10-15 is still fine, and below 10 and we have to work hard to make our miles. But cruising boats are at anchor 99% of the time. And when at anchor we like to be in sheltered bays and the lee of islands. First, so that we do not drag anchor and lose our boat, and second, so as to be calm and comfortable. So 99% of the time we are looking to minimize the wind on our boat other than a nice breeze.

In discussions with fellow cruisers that have installed wind turbines on their boats they report that the typically produces about 4 amps, and see peaks in the 10-15 amp range. It is a bit misleading when you see a wind turbine that promises 400 watts / 12 volts = 33 amps and you get just 4-6 amps right? What is happening here is that wind turbines only produce their 400 watts when the wind is blowing at the very top of their operational range.

The nice thing about wind, is that it may blow day or night, so in an ideal tropical anchorage perhaps we see 5 amps an hour, 24 hours a day, or 120 Amps-hours per turbine, so we would need 3 turbines and ideal conditions. I have seen a lot of catamarans with 2 turbines, but I have never seen 3 turbines. And most of the time it is not ideal and the turbines are just not making power. And on the rare day that the wind picks up to 35+ kts you are trying to stop the turbines so that they do not damage themselves.

And they are always making noise. Usually enough to be annoying to neighboring boats, let alone the crew!

We are tropical sailors. We are following the trade-winds around the world as slow as possible. While there is often rain in the tropics, we get lots and lots of sunshine. Being a catamaran, we have a lot of real-estate, so there is plenty of space to mount solar panels. We have installed (8) 265 watt solar panels for 2100 watts of solar power, or 175 Amps of theoretical power. On a typical tropical day we see actually 120 amps across the hours of 10 am to 2 pm, and significant power staring at 7 am and ending at 5pm, all-in our typical solar day produces over 700 amps-hours! That is almost 2x our more normal daily consumption! Compare that to two turbines in ideal conditions that might produce 240 amps-hours.

Solar kicks the snot out of wind.

For small boats.

For industrial scale power production, wind and solar are very complimentary.

Energy Storage >> Energy Generation

Okay that is our power generation, but getting back to the start of this essay – Lithium! We need to store this energy from solar that we are producing so that we can use it across the night and into dark and rainy days.

Storage is more important than generation, for what good is your generation if you cannot use that power when you need it?

Why is Lithium – specifically LiFePO4 better than the fancy Lifeline AGMs?

Two killer reasons; and then two more reasons to take it over the top.

First, Lithium is very happy to be drained from 100% to 10%

Second, Lithium charges linearly – meaning that you simply have to put back the energy you used, not a crazy asymptotic curve like with lead. This means incredibly faster charging times to get to 100%, and a much large range of use of the house battery bank.

So we had 1100 Ah of lead that is 30% usable, to size it in lithium which conservatively can be drained to 80% then we need to solve the equation of 30% * 1100 = 80% of x? = 412 amp-hours of Lithium to get the equivalent of 1100 Ah of lead.

- The third is that Lithium is about 25-33% the mass of lead system, and being a catamaran we like to be light! Saving 500 pounds of weight translates into materially faster passage making and more beer-capacity.

Lithium is cheapest!

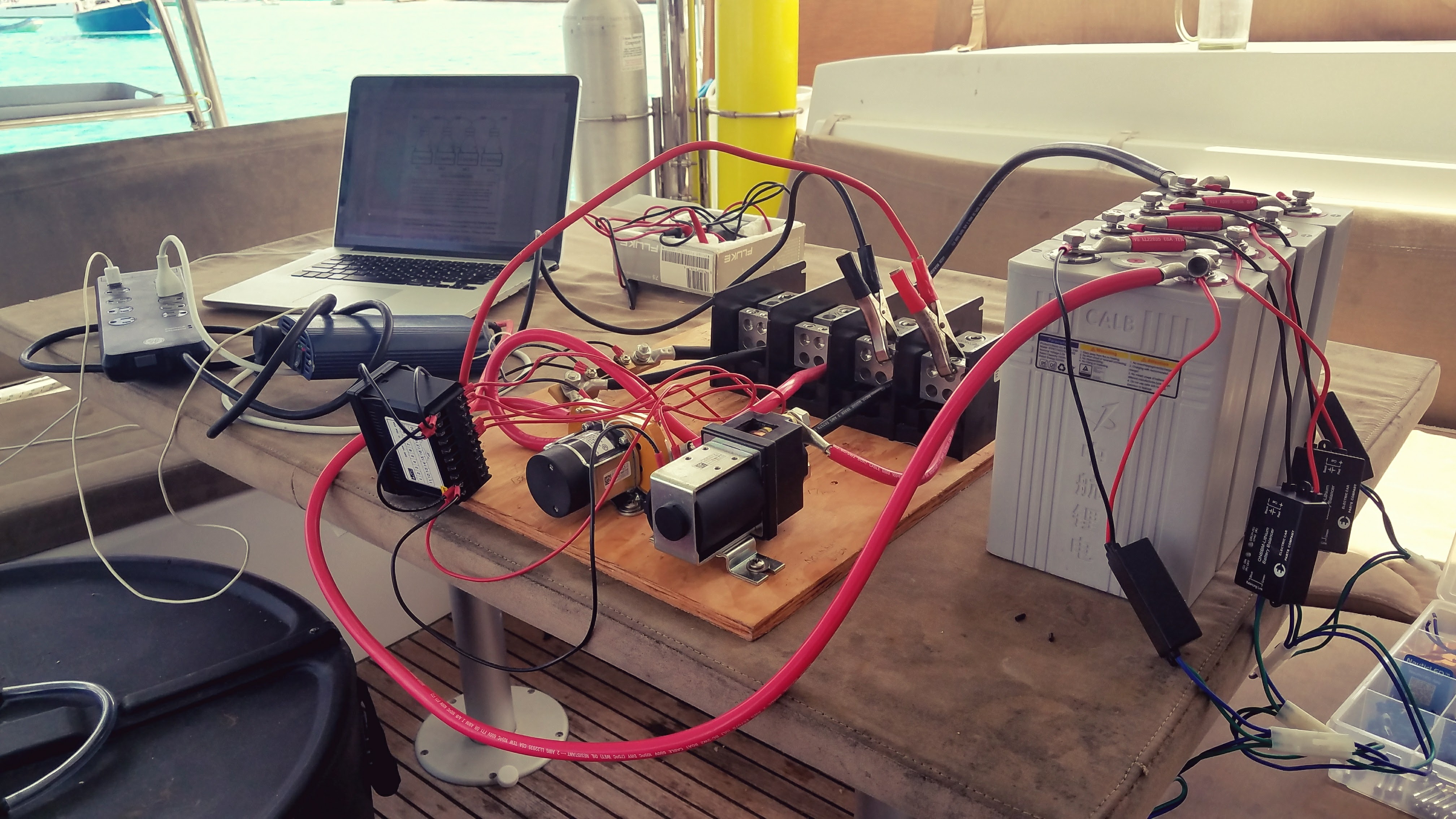

The full 48 cell, 4s12p on a dry-run setup on the cockpit table, complete with the BMS

- The fourth great reason for Lithium is that you get at least 2000 cycles and possibly even 5000 cycles, or somewhere between 4-10x longer lifetimes! This makes Lithium actually CHEAPER than lead-acid house banks.

So if all I needed was 412 Ah of Lithium, why did I go for 1400 Ah?? Well, when building a power plant I think it is wise to plan for future consumption expanding. Second, even with the energy hogs that we are, I have to start and stop the inverter to produce the 110 v power for the macs & washing machines and over-all spend a decent amount of the day concerned about power. Truthfully, I still did not know what was our ideal upper bound of energy consumption. I wanted to have the land lifestyle where we could plug our crap in and forget about it!

So I wanted more than 400 Ah of Lithium. I thought about 600, 700, 900 or 1000? Eventually I decided on 1400, because that was where the price point breaks down for a full pallet of 48 “cells”. It is about a 10% savings.

Cells

I am getting ahead of myself, why I am now talking about cells and not batteries? There are two ways to go with Lithium: turn-key, packaged, marinized batteries from ReLion or MasterVolt or building your Lithium bank from raw cells.

The pre-packaged solutions are nice – they have a form factor that looks just like your current deep cycle batteries, they have the same single positive and negative terminal, and they have solid warranties. But most important, there is circuitry inside of these pre-packaged batteries that perform three safety functions – protection from over-charging, protection from under-charging and cell balancing. So that is a pretty awesome set of positives – but for that these companies charge about 2.5 to 3.5x the cost of the underlying cells. So instead of $6k for cells it could be 15-20k for a turn-key solution. That is a lot of money.

So I went online and did a lot of research, and asked a bunch of questions, and to be honest, I really did not get very many good answers. Most of the lithium knowledgable folks online are trying to make some money on the side by selling consultation. I get it. But I have multiple freaking aerospace engineering degrees that took me many years to pay off. I should get a return on it. So, I dug more, I went to the spec sheets, read some white papers, and read between the lines of many posts. Then I talked to the guys at The Electric Car Company. They had the best deals on raw cells.

At the end of the day it just is not that complicated. You want to protect your lithium cells from being overcharged, you want them to be protected from under-charged, and most subtle of all – especially for a many cell system – but really any Lithium setup – you want ALL of your cells to have the same voltage at all times. Three things:

- Over-charging

- Under-charging

- Balanced Voltages The under and over charging is probably common sense – you will burn out or burn up your battery. But the balancing needs some extra discussion:

To understand balancing you need to understand the over and under-charging scenarios. Basically an outside circuit measures the “open-circuit” voltage of your house bank and if it is over say 13.8v (3.45v per cell) it stops charging and if is under say 11.8 volts it cuts off the delivery of power. But the devil is in the details, the way that voltage is measured is by what the positive and negative terminals at the house bank terminals are showing. There is NO internal measurement of the individual cells.

The result is that over time, or by poor wiring (see below), you have some cells that have wandered about in voltage space with lower or higher voltages than their peers. But it is just the average (roughly hand waving) voltage, with some cells below and some above this aggregate voltage you are going to end up over-charging some cells and under-charging others and causing permanent damage.

So you need all of your cells to be the same voltage. How do you do that? You need to do two things:

“top-balance” you wire up all of your cells into a single massive parallel 48 cell x 3.45v bank – and then you simply let them sit. For weeks. The longer the better. Basically the over-charged ones will charge the under-charged ones until they are all equal.

Max is top-balancing the cells

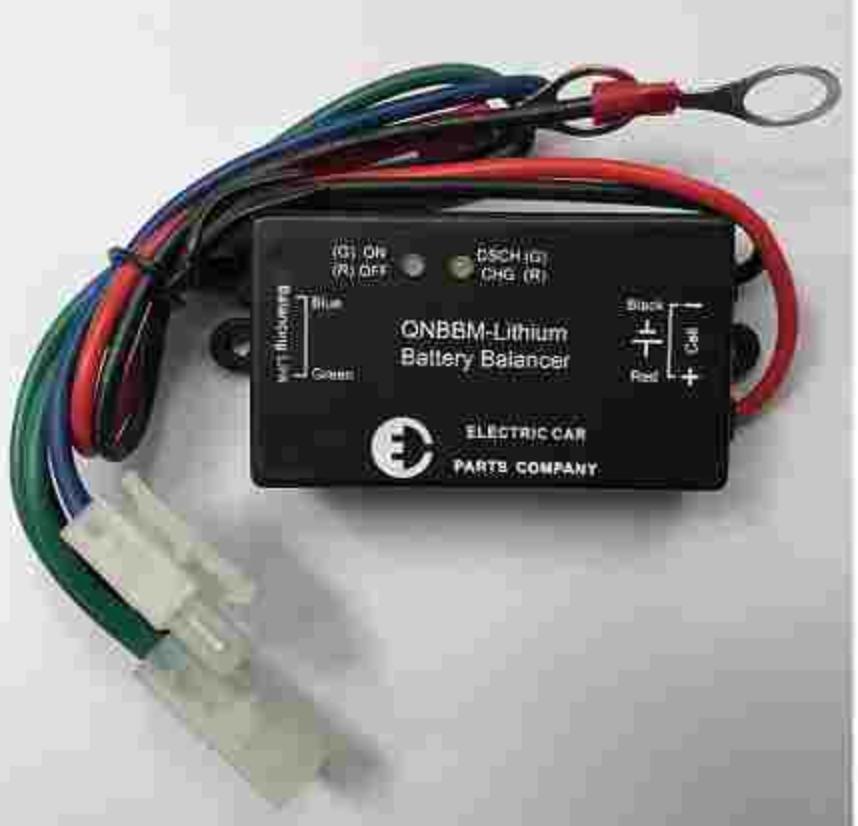

Then you use a battery-management-system (BMS) to keep them equal. What is a BMS? It is basically a mini voltage meter + battery charger, and you need one for EACH cell. Then you wire these guys all up the same as you are wiring up your cells into series and parallel (see below) and what they do is keep checking the voltage on their neighboring cells and keep micro-charging back and forth to keep them at the voltages

BMS

If you are really diligent then every 18-30 months you will tear your cells apart and go back and “top-balance” them again for a week or two. This implies you have access to a secondary source of house power (a marina). And you are willing to do the labor of unwiring, wiring, unwiring and wiring your cell network. For Ad Astra’s 48 cells this would be a lot of work, probably about 40 hours for two people every two years. I am going to hope that our digital multimeter shows us nice even charges two years from now (see below).

Okay, so again MasterVolt and ReLion have these three features: over, under and BMS packaged in, but they charge 3x for that.

Over-charging:

We have a Xantrex 3000 Inverter/Charger and it has software programmable charging profiles, so we can simply set a high voltage cut-off for it to stop charging the batteries.

Our 8 solar panels are arranged into 3 separate arrays of 36v 36v and 24v going into 3 different Outback MMPT controllers (fancy DC to DC converters that can take any range of input DC and give you a clean amount of DC at whatever voltage you want – like 14.4) and again software shuts off if too high.

Our Hitachi 80 amp alternators have no such fancy software controls. So this is a potential problem right?

So, we do not need the pre-packaged solutions for over-charging except perhaps for when the engines are running. But we do not run the engines for making electricity, this is only a potential problem if we have multiple days on end of motoring. But even then, add the auto-pilot and the navigation to our already energy hogging lifestyle and we are at 50+ amps per hour. That is a good fraction of those alternators, and so we will charge up the bank, and worst case – do lots of laundry and leave the fridge doors open! Ha! Or realistically – shut off an engine. (There are some sort of shunts I can buy to safely divert this power coming out of the alternators.) But I convinced myself that I do not have an over-charging problem.

So under-charging?

Well yes, so I went with the recommendation from The Electric Car Company to buy a voltage monitoring relay. The problem with this relay is that it uses a ton of power to keep its magnets engaged, and when low on power it fails to power the magnets and that is what cuts the circuit. This thing alone turned out to be our biggest energy guzzler! So I ripped this power leach out of system after the first build (see below). Instead, for under-charging we simply have gone back to what the boat came with – the main’s low battery alarm. But in practice with sunny days, our house bank is full and at 13.0 volts pretty much 24×7! (This is a really big deal. We can go through 2 days of little sun.)

BMS

Yes, these area great and necessary, they are not something you can skip or leverage from your existing chargers and controllers. They are about $22 each and you need one for each cell. Wiring them up takes a small amount of care, but they have friendly green and red lights telling you that they are doing their job. Since I built a nominal 12v system, I wired 4 BMSs in series, one for each of the cells that made up the series section of the battery (see below Series & Parallel).

Series and Parallel

Max is the perfect size to do the final wiring inside the battery bay

Okay, when you go online and look at people discussing their scratch-built lithium systems you will quickly come across people saying something like: “I have 600 Ah in 4s6p” or “400Ah in 4s2p” how do you decode these symbols that look like electron orbits around an atom?

4s means “4 cells in series”

6p means “6 (of the series groupings) in parallel”

What does that mean?

Okay, LiFePO4 cells are fully charged at 3.65 volts, but we need 12-13 volts to supply our system, so what you do is simply connect 4 of them in a string with positive to negative to create a 3.65 * 4 = 14.6 volts when fully charged, and more typically they hang out around 3.25 volts each or about 13.0 volts when 4 of them are in a string. Perfect.

That gets our voltage, but what about the storage capacity of the bank? That is measured in Ah (at the nominal 12v) and in the first example above “600 Ah in 4s6p” take the 600 Ah and divide it by the number of of parallel groupings of the 4 in series. In this case, take 600 Ah / 6p = 100 Ah. Now it is clear what someone has built: they bought 24 individual 100Ah LiFePO4 cells (approx $125 each) and made 6 different series strings of 4 cells to create a total capacity of 600Ah at the nominal 12v. For a 24v system, these same 24 cells would be wired 8s3p and would yield 300 Ah of storage, but now at double the voltage.

In the second example, 400 Ah in 4s2p, take the 400 Ah / 2p = 200 Ah cells, and there are 8 total of these cells, 2 different strings of 4 in series and then wired in parallel.

LiFePO4 cells are available in a variety of Ah sizes (and the price is relatively linear with size at about $1 per Ah). Typical sizes are 40, 75, 100, 180, 200 and even 400 Ah!

Ad Astra’s House Bank: 1418Ah in 4s12p

For Ad Astra, I chose Calb nominally 100 Ah cells, but happily the 100 Ah is the guaranteed minimum capacity and I found that my cells delivered averaged at 118 Ah each – a very healthy bonus 18% of capacity! So we have wired up 12 different strings of 4 cells in parallel to create 12 x 118 = 1418 Ah of capacity.

Maybe you are asking why did I sign myself up for wiring 48 cells together? Why not buy the 400Ah cells and make it a 4s3p system for the same 1200 Ah nominal size? One reason is price. Previously I said that pricing is linear with capacity, the truth is that it is mildly exponential with increased capacity and so 400Ah cells cost about 35% more than 4 100 Ah cells.

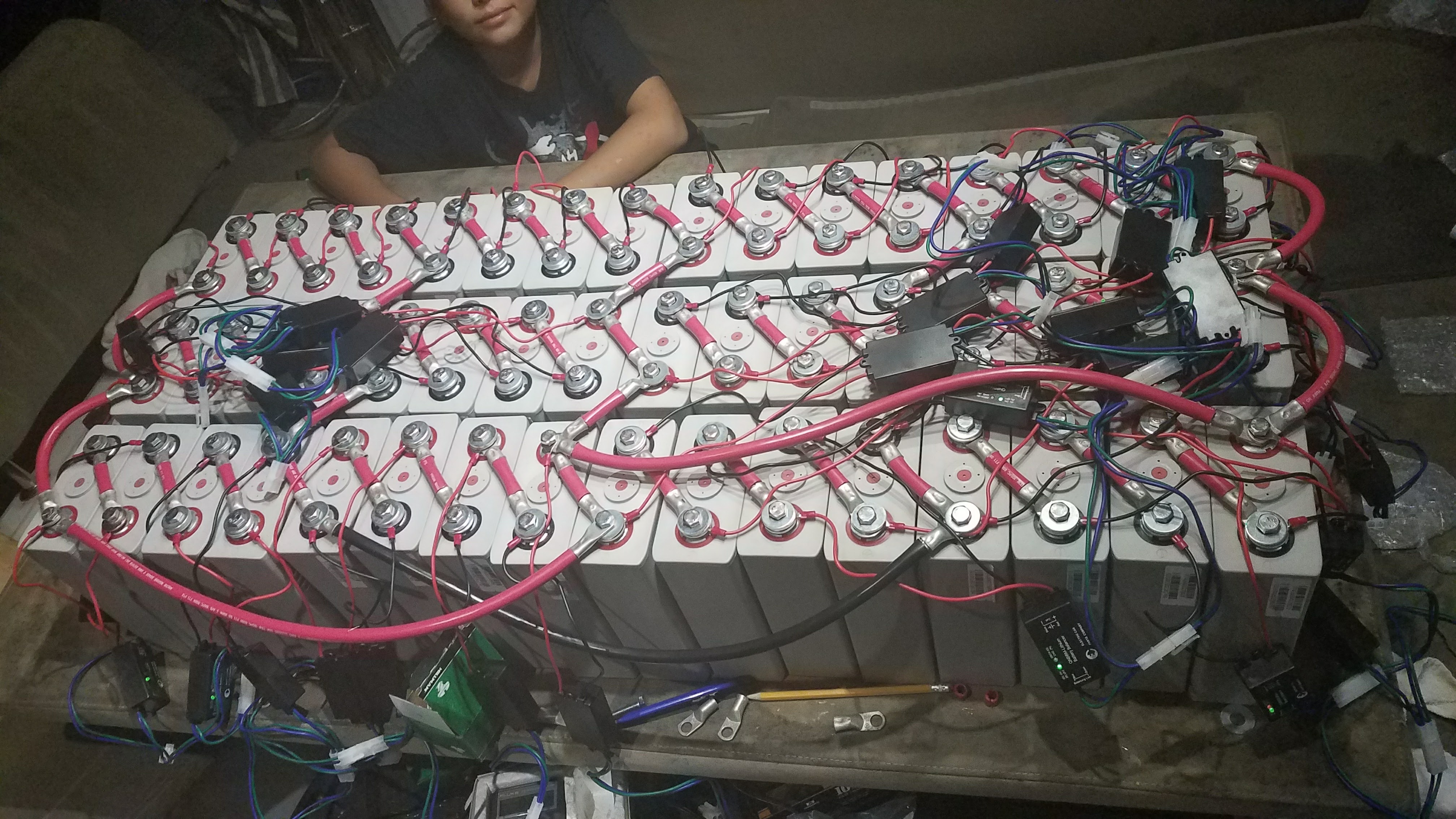

48 of these cells make up our house bank

100 Ah Calb cell sourced from The Electric Car Company

Modularity

That 35% savings is substantial, the 48 100 Ahm cells have a cost of about $6,000 which would have added $2100 more to have the convenience of a 4s3p wiring.

However, there is another reason I went for the 100 Ah over the 400 Ah cells – modularity. That is, suppose one of these 400Ah cells goes bad? Then, not only do I lose a cell, but I have to take out the 3 other cells in that same series string, and instead of having 1200Ah, I would end up with 800 Ah in a 4s2p configuration. With $2k of idle cells.

Now with the 100 Ah configured in 4s12p, and I lose a cell, then I simply re-wire to a 1100 Ah 4s11p configuration. Compare losing just 8% vs 33% of capacity and being out just $450 instead of $2k of cells being idle.

Shipping your Cells

Special mention must be made to the shipping of your LiFePO4 cells. Being lithium based battery tech – very few airlines will ship the cells. That leaves, boats, rail and trucks.

Pallet of Cells

If you order enough cells – such as a full pallet of 48 like I did, then the cells will actually be drop-shipped directly from the factory in China to Long Beach, California. From there, my cells were shipped by truck to Miami, Florida, and from there by ship to Saint Martin, West Indies. The shipping costs were quite substantial at about $1500, and I would have saved probably about $1000 if I had chosen to pick them up in Miami, Florida. Adding on to the advantages of a highly modularity design, imagine if you get a bad cell dead on arrival after a very expensive shipping route? It simply will not make financial sense to ship that bad cell back to China, and back again. So practically you will likely have to eat a bad cell.

Our dinghy carries everything!

What went Wrong, Loose Ends and Do Differently?

As I discussed about the powered relay for maintaining a low-voltage cutoff turned out to be a huge power drain, and so I simply took it out of the circuit. Do I worry about ever dropping too low and damaging the Lithiums? No. We recently went to Mexico City for 5 days, and left the boat with house lights on in two cabins and of course the bilge pumps on standby. With no other systems to draw, the boat simply stayed at absolutely maximum charge. We can be extremely greedy and leave the inverter on overnight without fear of draining too far in single day. So, no frankly, we have no under-charging scenario.

The second time I wired up the 4s12p system after taking out the relay above, I was a bit haphazard where I attached the house, inverter/charger, and the three different solar MPPTs positive and ground leads. I was simply being lazy and assumed that since we have 12 parallel connection points, I could pick anyone of them and that the electricity will flow. That is true, the electricity will flow across the network, that is true, but it will flow unevenly if you attach willy nilly at different junctions in the parallel net.

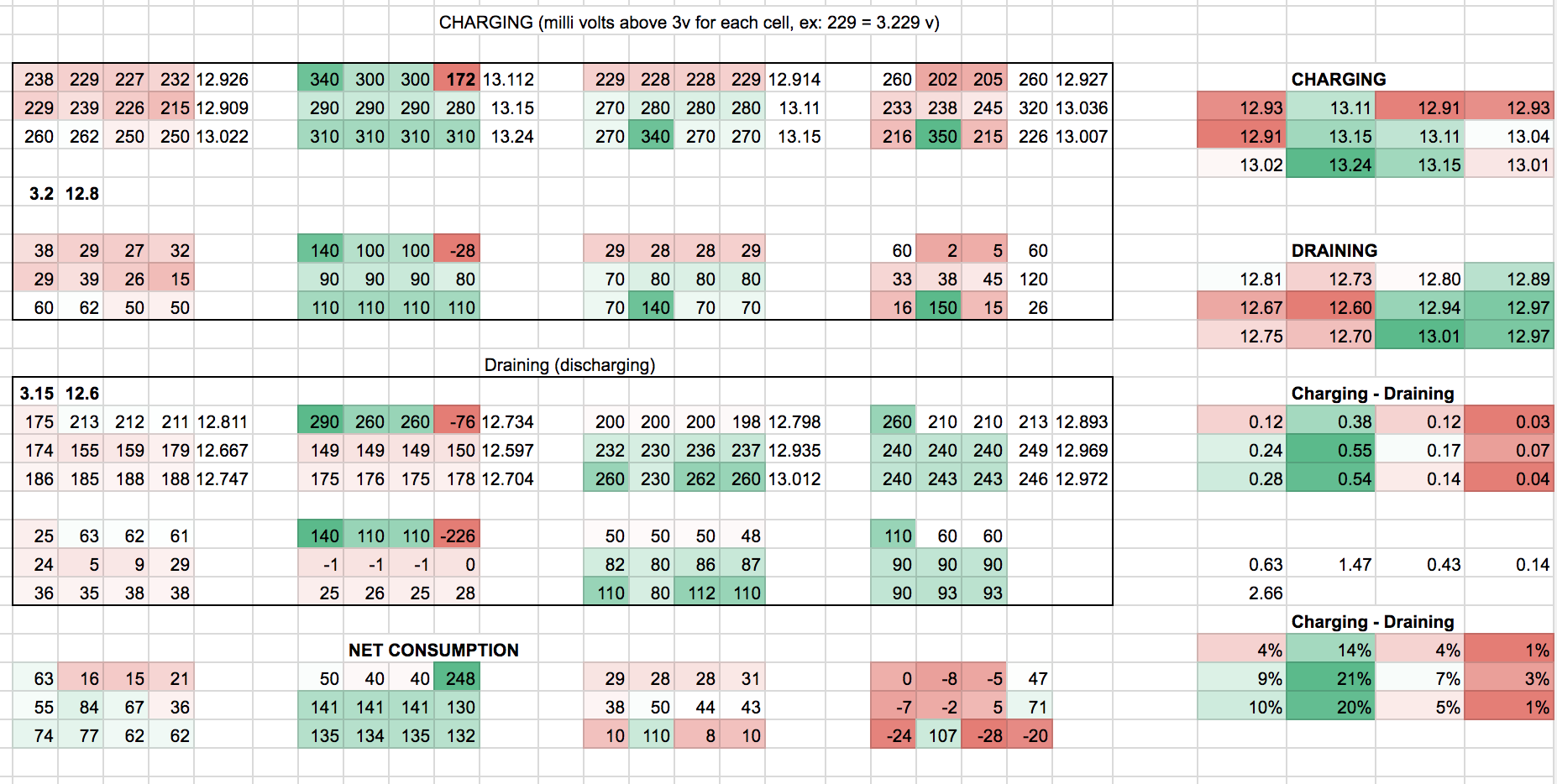

Experimentally, I was able to confirm the effect and you can see from these charts that just two of the 4s batteries were doing 40% of the over-all work! And 5 of them were doing 75% of the work. Practically, we did not have a 1400 Ah battery network, instead we had a 200Ah main bank, with another 300 Ah partially available.

Span the Full Network

This is what happens when you do not fully span the parallel network

Re-wiring the positive and negative to the extreme opposite ends of the network were an instant night and day effect. Working with limited supplies, I was still forced to wire the generator to stretch across just 11 of the 12 batteries, and the smallest of our solar chargers spans just 6 of the 12 batteries. So, 1500 watts of solar charges the whole network, 2000 watts on half. And that lonely 12th battery loses out on the rare occasion that we use the generator. The alternators span the full network now – as it is the same as the house supply leads. So, there are two cables I should create a some point.

This is really a boneheaded mistake. But I list it here for transparency and to highlight that it will absolutely dominate your bank’s performance.

Terminal Connectors

Making the terminal connectors – crimp hard!

My only real concern for my DIY Lithium setup is that for the 48 cells, I needed to manually crimp on about 100 heavy duty terminals. Mechanically, there is a definite possibility that my terminals will come apart due to vibration. To address this weakness, there are a number of companies that create excellent looking, flexible, braided terminal connections to your exact size specifications. When I ordered my cells, I did not quite know which way I was going to stack them, and so I did not know the exact length of the terminals I would need. Now that everything is all wired and in place, I do know the length. But now my frugality takes place as each of these larger terminals is about $0.80 down here in the islands, and the large gauge copper wire is super expensive, so I probably already have about $200 invested. I do not know what these custom terminals cost, but even at $2 a piece plus shipping that is $300, and I would not be surprised if they were actually $7 each. So what happens if one of these terminals fail? Potentially, I have a short-circuit if it mechanically wanders and makes contact with the wrong terminal. This is my current largest concern. Otherwise I now have 92% capacity with 4s11p. Simply re-crimp, or use one of our standby cables to bridge the broken connector.

Potential source for braided terminal connectors:

Speaking of vibration, the whole stack of 48 cells fit very nicely in the existing battery bay, but I did add in some thin boards to act like wedges around the perimeter to make sure it was very snug. This is a critical step as you want your cells to be a single solid state brick.

Other Pix

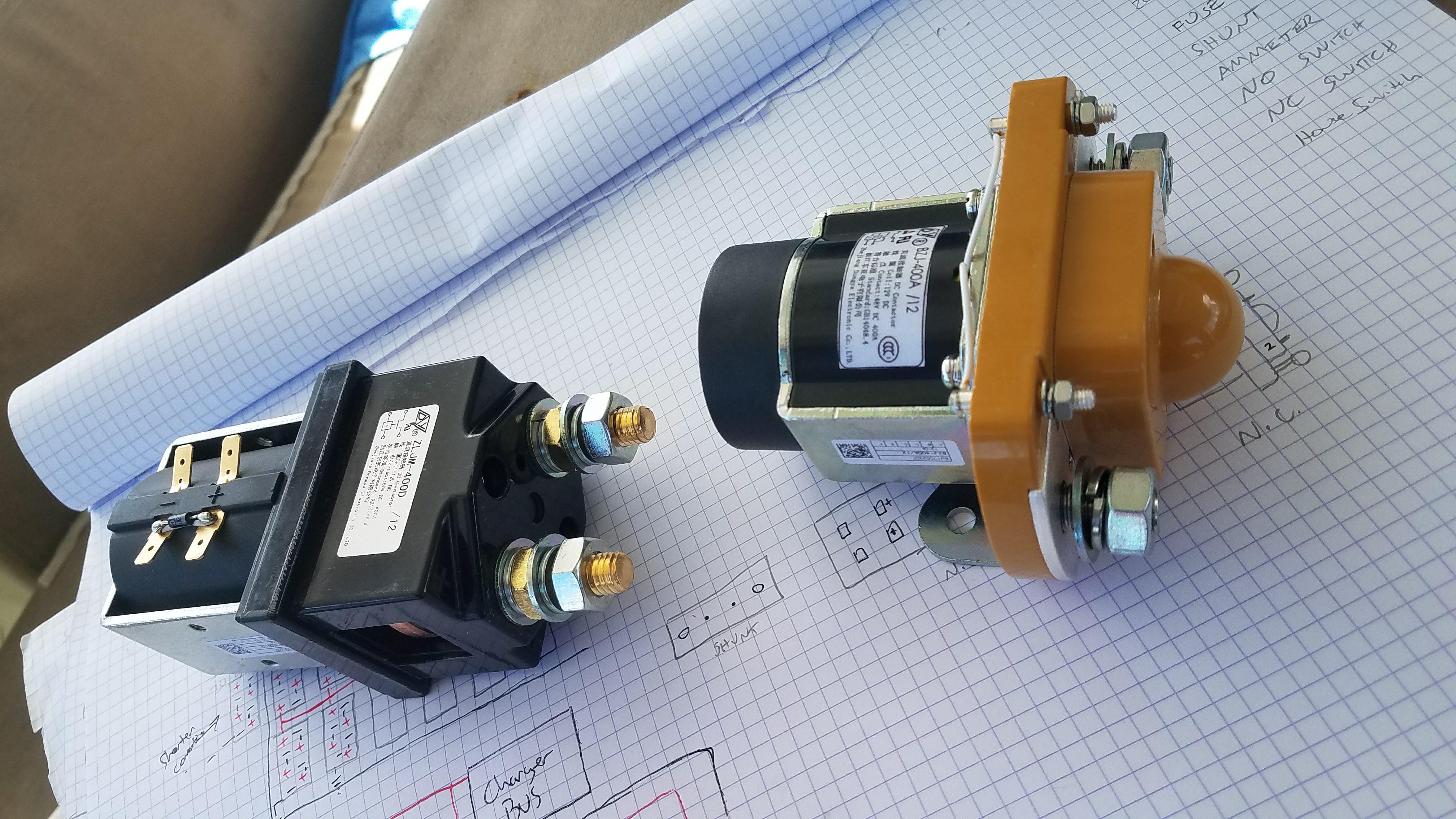

These are the heavy duty relays that burned up too much power

I loved the China Aviation custom packing crate - it was a work of engineering itself!

A close-up of a single pair of cells